10 Do’s & Don’ts for Your Grow Room-2

2023-03-04 17:00

6. Environmental Control

Do: Invest in your mechanical system and airflow design

Investing in mechanical systems and airflow design can often be the single most significant limiting factor in the success and profitability of an indoor growing facility. Comfortable, constant airflow is a must for any grow room, especially when growing vertically. Knowing the desired watering rate and setting can help you decide which system and design to invest in. Long term success is limited to good environmental control.

Don't: Invest in a system that can be easily expanded

If you're just starting out, consider what systems will be easier to upgrade once you start making money. If your budget is tight, try to find out ahead of time how you can save money on this system and set improvement goals based on specific revenue metrics.

7. Lighting

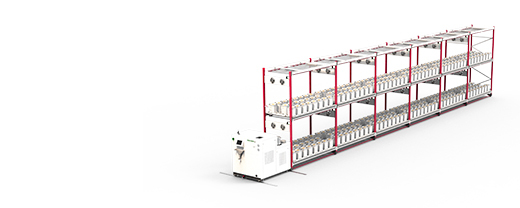

Do: Invest in LED garden lights

Since the introduction of LED lights in horticulture, the cost per light has come down drastically. Nearly every facility built today uses LED lighting due to joule efficiency, spectrum and form factor. Additionally, you can often offset the cost of these devices with utility rebates from your local utility company. LED lighting can support the operation of cannabis indoors by optimizing plant growth at every stage of the plant life cycle. Learn how vertical farming technology can enhance your indoor cannabis operation!

Don't: Waste your time and money with HPS lighting

HPS technology can be inefficient at converting electrical energy into usable plant light. All the heat generated with HPS lighting requires more cooling power to dissipate. Since vertical farming adds several levels of growing space, investing in LED lights will be essential to maintain temperature.

8. Employee Considerations

Do: Train employees on your system

It's important to train your employees so they know exactly what needs to be done each day. Especially with vertical farming systems, vertical farming requires different training than single-tier systems. Limit the number of specific tasks per employee and let them master a job before training them for a new job. Walk before you run! Labor is the highest cost of production per pound; A good team, confident in their work and taking care of the factory, will lead to a profitable and successful business. Make their daily life more comfortable; An employee who is happy to come to work will do a better job.

Don't: Assume everyone knows the process, even if they say so

Employee mistakes lead to injuries and absenteeism due to lack of training. Growers need to constantly update their SOPs and ensure their employees are following the latest procedures. The cannabis industry is a fast-paced environment and things can change overnight. Have a method to track employee performance and build a dedicated and professional team to achieve specific goals and achievements!

9. Cleanliness

Do: Take care of your facilities and improve room cleanliness

A clean facility means healthy plants that produce higher yields. Design facilities that are easier to clean and plan drains, sinks and systems to allow for more efficient cleaning procedures. Proper environmental and airflow management reduces the risk of pathogen spread. The worst feeling a farmer can have is failing lab tests and not being able to sell a crop they just spent 3-4 months and tons of money growing.

Don't: Be Lazy

Corner cutting will result in poor yields, poor airflow, and unhappy plants. Dirty facilities without proper reset and disinfection protocols increase the risk of laboratory test failure and often reduce results. Growing quality cannabis indoors is not guaranteed; The more work and attention you put into your plants and facilities, the more you will be rewarded.

10. Balance

Do: Consider every parameter, metric, and KPI in your growth space when it comes to balance sheet

Balance is the key to successful grow room design and operation. Is your watering rate in balance with your dehumidification capacity? Are your lighting levels keeping up with your CO2 levels? Energy in = energy out. Growing indoors is all about balancing energy; in every system and company for success.

Don't: Narrow your focus

Every system and growth parameter in your grow room works in harmony and synergy. If you are only thinking about fertilizing decisions or watering strategies, you need to consider how they affect every other parameter to avoid imbalances. Balance your production process flow, labor and time requirements, genetic rotation with production and growth parameters. Balance is the key to success.

Get the latest price? We'll respond as soon as possible(within 12 hours)